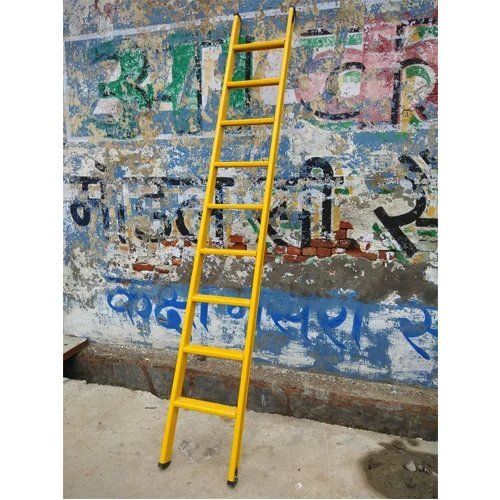

FRP Extension Ladder

Price 450 INR/ Foot

FRP Extension Ladder Specification

- Type

- Industrial Ladders

- Material

- FRP

- Structure

- Extension Ladder

- Usage

- Industrial

- Size

- 10 TO 60 FEET

- Feature

- Heavy Weght Capacity, Non Breakable, Excellent Grip, Rust Proof, Maintenance Free Usage, Non-Skid Surface.

FRP Extension Ladder Trade Information

- Minimum Order Quantity

- 1 Foot

- Supply Ability

- 100 Feet Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About FRP Extension Ladder

A FRP (Fiberglass Reinforced Plastic) Extension Ladder is a type of extension ladder made from fiberglass, a material known for its strength, durability, and resistance to electrical conductivity. This makes it ideal for use in environments where safety, particularly against electrical hazards, is a primary concern. Below is a detailed description of an FRP extension ladder, including its features, benefits, and typical uses.

Key Features of FRP Extension Ladders:

-

Fiberglass Construction:

- The primary feature of an FRP extension ladder is its construction from fiberglass, a composite material made of fine fibers of glass embedded in a resin matrix. This gives the ladder a high strength-to-weight ratio.

- Fiberglass ladders are non-conductive, making them ideal for working around electricity or electrical equipment without the risk of electrical shock.

-

Extension Mechanism:

- Similar to traditional extension ladders, FRP extension ladders consist of two or more sections that can slide to extend the ladder to various heights.

- The sections can be locked securely in place using a reliable mechanism to ensure the ladder remains stable while in use.

-

Non-Conductive Properties:

- One of the most important advantages of fiberglass is that it is non-conductive, meaning it will not conduct electricity. This makes FRP extension ladders perfect for use in environments with electrical hazards (e.g., utility work, electrical installations, or maintenance around power lines).

-

Corrosion and Weather Resistance:

- Fiberglass is resistant to corrosion, making it ideal for outdoor use, even in harsh weather conditions. It will not rust or degrade in the same way metal ladders can, which enhances the ladders lifespan and durability.

- The material is also resistant to chemicals, oils, and other corrosive substances, making it suitable for use in industrial settings.

-

Lightweight Yet Strong:

- Despite being made of fiberglass, these ladders are relatively lightweight compared to their metal counterparts, making them easier to carry and maneuver.

- FRP extension ladders maintain a high load-bearing capacity, which means they can support heavy weights while still being portable.

-

Safety Features:

- Anti-slip feet: The bottom of the ladder usually has rubberized or non-slip feet to provide extra stability, especially on smooth or uneven surfaces.

- Wide rungs: The ladders rungs are designed for comfortable and secure footing, ensuring that the user remains stable while climbing.

- Locking Mechanisms: The ladder sections come with reliable locking mechanisms that keep the ladder extended at the desired height safely.

-

Weather-Resistant Coating:

- Many FRP extension ladders come with a weather-resistant coating to further enhance their durability against environmental factors like UV rays, moisture, and extreme temperatures.

Common Uses of FRP Extension Ladders:

-

Electrical Work:

- Utility and Power Line Work: FRP extension ladders are commonly used by electricians, utility workers, and power line maintenance crews because of their non-conductive nature, offering protection from electrical hazards.

- Wiring and Electrical Installations: Ideal for accessing high places when performing electrical work, such as wiring installations, electrical panel maintenance, or light fixture installations.

-

Construction and Maintenance:

- Roofing and High-altitude Construction: Used in roofing and construction tasks where workers need to access tall structures or buildings.

- Building Inspections: Inspectors use FRP extension ladders to assess building exteriors, rooftops, or elevated structures in a safe manner.

-

Outdoor and Industrial Use:

- Industrial and Warehouse Work: FRP extension ladders are used in industrial settings where workers may need to access tall storage racks or machinery. Their resistance to corrosion makes them suitable for environments with chemicals or moisture.

- Tree Maintenance: FRP extension ladders are also useful in landscaping and tree care, allowing workers to safely access branches and tall trees.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in FRP Ladders manufacturers Category

FRP Self Supporting Ladder

Price 13500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Feature : Heavy Weght Capacity, Non Breakable, Excellent Grip, Rust Proof, Maintenance Free Usage, NonSkid Surface.

Type : Industrial Ladders

Size : Standard

FRP Folding Ladder

Price 450 INR / Foot

Minimum Order Quantity : 1 Foot

Usage : Industrial

Feature : Heavy Weght Capacity, Non Breakable, Excellent Grip, Rust Proof, Maintenance Free Usage, NonSkid Surface.

Type : Industrial Ladders

Size : Standard

FRP Straight Ladder

Price 460 INR / Foot

Minimum Order Quantity : 1 Foot

Usage : Industrial

Feature : Heavy Weght Capacity, Non Breakable, Excellent Grip, Rust Proof, Maintenance Free Usage, NonSkid Surface.

Type : Industrial Ladders

Size : width 16 inch

Fiber Reinforced Plastic Ladder

Price 1500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Feature : Heavy Weght Capacity, Non Breakable, Excellent Grip, Rust Proof, Maintenance Free Usage, NonSkid Surface.

Type : Industrial Ladders

Size : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free